| |

|

CLARCOR Industrial Air has been providing industry leading filtration solutions to our customers for 50 years. As part of the world's most diversified filtration company, we bring you unparalleled technical knowledge of industrial applications and innovative filtration technologies.

|

Technical Resources & Information |

|

|

|

Clarcor Industrial Air

Replacement Dust Collector Filters | Dust Collection Equipment

Dust Collection Equipment

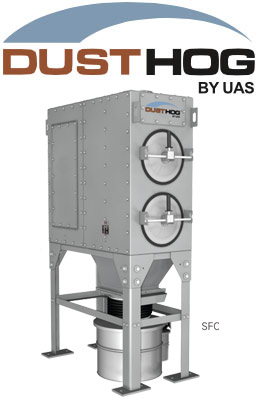

Dusthog® Dust Collector SFC Series Dusthog® Dust Collector SFC Series

|

|

The DustHog® SFC is a proven, high-quality downward flow cartridge dust collection system. With its patented pulse cleaning technology, greater air capacity and quick and easy maintenance, there’s no better air filtration method for your manufacturing facility.

Our SFC unit removes harmful pollutants resulting from common manufacturing processes — such as grinding, welding, buffing and sanding. The result: a safer, cleaner environment for your employees. By using our SFC unit, you’re virtually eliminating air quality concerns in the workplace. Plus, you’re ensuring increased employee productivity, fewer absences and illnesses, more efficient cleaning, and significant operational savings.

. |

Ceiling-mount Models SCA/SCB Dust Collectors Ceiling-mount Models SCA/SCB Dust Collectors

|

|

Ensure effective dust collection even when floor space is limited with SCA / SCB ceiling-mount cartridge dust collectors. Model SCA provides ambient air cleaning enabling workers to move about freely, while the SCB is equipped with two XA Extraction Arms for excellent source capture. Available for 2,000 and 2,500 CFM (1,000 CFM per arm on Model SCB), both dust collectors ensure easy, tool-free dust drawer and cartridge filter change outs.

Models SCA / SCB Cartridge Dust Collector Features

- Inlet baffle - slows down air for even distribution to cartridges and improves overall cleaning

- "QuickSeal" release doors - provide fast filter removal and maintenance with one simple hand movement

- Safety cable - secures "QuickSeal" release doors while filters are changed overhead

- Optimized cartridge cleaning system - offers maximized cleaning power as a result of spring-fee-pulse valves and optimized nozzles

- Removable dust drawers - offers large-capacity storage and easy removal of collected particles

- No internal yokes - allows cartridge rotation, which aids in dust release

- External motor / blower - offers easy access for routine service and maintenance

- Magnehelic or optional photohelic pressure gauge - monitors pressure and indicates when filters need to be changed

- Powder- coated finish - prevents fading and chalking

. |

MCB Series Cross Ventilation Dust Collectors MCB Series Cross Ventilation Dust Collectors

|

|

The most efficient, quiet and cost-effective system for cleaner factory air.

When it comes to superior dust collection, there’s no better choice than the DustHog® MCB Series Cross Ventilation Cartridge Dust Collector. Designed by the leading air quality experts at CLARCOR Industrial Air, this completely self-contained system provides high-filtration efficiency, freedom from source capture obstructions and easy maintenance. Plus, it offers versatile configurations — available as a single unit or in combination with a containment booth.

A Wide Range of

Applications

Ideal for applications where source capture is impractical, MCB units remove fine airborne dust resulting from a variety of finishing operations. Because workers benefit from complete freedom of movement, excellent lighting and a clean breathing zone, they can easily perform any type of manufacturing process— from grinding, sanding and welding

to abrasive blasting, batch mixing and powder coating.

. |

Source Capture Solutions: Extraction Arms, Hoods & Accessories Source Capture Solutions: Extraction Arms, Hoods & Accessories

|

|

Capture, Extract, Filter

The most effective and energy-efficient way to control nuisance airborne emissions is to collect the pollutant at or near the source of generation. The benefits of source capture include:

-

Reduced facility cleaning and maintenance by preventing pollutant migration.

-

Improved worker health by protecting the breathing zone from harmful pollutants resulting in higher productivity plus lower absenteeism due to illness.

-

Lower operational costs by capturing contaminants at the source which requires the least amount of energy consumption.

-

Achieve a cleaner and healthier workplace and stay compliant with environmental regulations by stopping the spread of fumes, smoke, dusts and other airborne pollutants at the source with United Air Specialists’ extraction arms, telescopic arms, hoods and accessories.

. |

V-Series Factory and Industry Smoke and Dust Collectors V-Series Factory and Industry Smoke and Dust Collectors

|

|

If you’re looking for a versatile, cost-effective alternative for eliminating fumes and dust in your factory, look no further than United Air Specialists’ V Series. This innovative cartridge dust collection system is specifically designed to capture the smoke, dust and powders that result from a variety of manufacturing operations. With a choice of two compact, low-profile sizes—750 or 1,500 CFM —the V Series truly is the most economical solution for cleaner factory air.

The V Series is available in three configurations: an integrated downdraft bench, a portable unit with swing arm and a free standing system. Installation is simple, requiring an electrical connection and a compressed air connection for the in-place cleaning option. Most importantly, because the V Series removes dangerous contaminants that can cause respiratory problems, it helps your factory comply with OSHA regulations and may reduce lost work time. Plus, it prevents dusts from migrating to areas with sensitive electrical and mechanical equipment— reducing facility maintenance, too.

|

W-Series Weld Fume Dust Collector W-Series Weld Fume Dust Collector

|

|

Through efficient removal of weld fume particulate, you can protect your workers’ health, improve productivity and reduce lost time due to illness. The most effective method of capturing weld fume particulate from a welder’s breathing zone is to collect it directly at the source. This is a difficult task given that up to 95% of weld fume particulate is submicron (less than 1 micron) in size. Particles in this size range are considered respirable, or so small that they simply pass through the body’s normal filtering system and directly into the lungs.

UAS is serious about clearing the air of weld fume particulate, and has developed a unique line of proprietary solutions for welding applications. We’ve combined our exclusive ProTura® Nanofiber cartridge filter with a series of portable and wall-mount systems for the source capture of weld fumes. These advanced technologies were engineered together specifically to achieve industry-leading filtration efficiency on submicron sized weld fume particulate, while enabling strong, long- lasting airflow to effectively capture weld fumes at the point of generation.

|

New SHM SmogHog® Media Mist Collector New SHM SmogHog® Media Mist Collector

|

|

SmogHog® means effective and efficient removal of mist and smoke for customers in the metalworking industry. For half a century our technical experts, application engineers and UAS representatives have been bringing you the right solution to protect your facilities from metal working fluids.

PEACH® Saturated Depth Coalescing Media. The technology was engineered specifically to capture oil mist and coolant contaminants. The media provides an open 3-D depth matrix structure which allows liquids to saturate the media depth and then drain with gravity, all while maintaining a low differential pressure.

Check out our PEACH videoto see how the world class filtration media works. Learn about the three tortuous flow paths created in this filter and the patent pending inner filter tube, each working to remove nearly all contaminants. The PEACH filter outperforms by:

- extending filtering capacity

- delivering high efficiency

- extending filter life and low pressure drop over time

|

|

|