| |

|

|

Mott Corp – Liquid-Solids Process Filtration

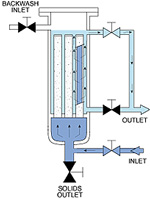

HyPulse® LSI

|

|

HyPulse® LSI filters incorporate inside-out filtration, a method and design unique to Mott Corporation. At the end of each filter cycle, solids are backwashed off the inside of the elements and discharged as a concentrated slurry or wet cake.

|

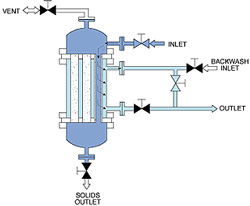

HyPulse® LSM

|

|

HyPulse® LSM filters place inside-out filtration within a double open-ended design. High-density solids are allowed to settle directly into the discharge hopper. LSM filters may be operated on a filter/backwash cycle schedule, or can be used as concentrators in a recirculating system. |

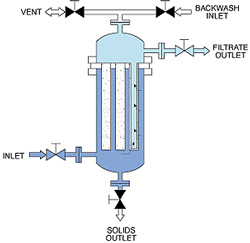

HyPulse® LSP

|

|

HyPulse LSP filters offer conventional outside-in filtration for polishing low solid streams with flows under 100 ppm. Easy to use and maintain, LSP filters provide reliable, permanent filtration that outperforms other types of media in a number of ways: |

HyPulse® LSX

|

|

HyPulse® LSX Process filters provide uninterrupted filter cycle performance through cross-flow filtration. Slurries flow through the open-ended filter elements, allowing filtrate to exit the system on a continuous basis while particulates remain in the recirculating stream. This is the ideal filtration method for slurries with unique particulate characteristics, or for achieving maximum retention of valuable particulates such as expensive catalysts. |

Applications

Chemical Processing: Catalyst Filtration / Catalyst Recovery / High Temperature Liquids / Guard Filtration for Fixed Bed Reactors / Industrial Wastewater Filtration / Recovery

Refinery: FCC Slurry Filtration / RFCC Slurry Filtration / Continuous Catalytic Reforming / Amine Filtration

Petrochemical: PTA / CTA / IPA / Polypropylene / Polyethylene

Power Generation: High Temperature / High Pressure Water Filtration / Precoat Septa

Nuclear: Reactor Water Clean-up / Condensate Polishing / Wastewater Filtration

Food and Beverage: Catalyst recovery from hydrogenation reactors / Polishing of syrups & liquors / Catalyst removal from flavor ingredients / Activated carbon removal, decolorization |

|

|